|

01/13/09 Bunch of progress on all fronts (see the other pages for more). On the dp4 end of things, the plug is coming along nicely. That CNC machine is pretty damned cool...

A lot of detail design work is taking place as well but more on that later, when there's something picture worthy. In the meantime, I've experimented some more with renderings. Just because.

02/01/09 Got some additional pictures of the plug being prepped. It's pretty hard to take pictures of a large white object in bright sunlight so these are a bit over-exposed, but they give an idea of what this device will look like in real life.

Of course the actual car will sit about 6" lower but the shots next to the Mini, especially the last one, give some sense of the scale. The photoshopped version below is close to actual size. Consider that the two cars in the picture would have roughly the same power but the dp4 should weigh a bit less than 1/4 as much as the Mini does, and will be AWD to boot. Cost should be roughly the same too, so while a Mini is a very fun toy I know which one I'd rather be playing with on a racetrack :)

02/13/09 The plug prep is nearing completion. Having done this stage myself on the dp1 prototype, I have a full appreciation for the amount of work involved. While there is a certain satisfaction to shaping something directly by hand, one of the things I learned from the first prototype is that some work is best left to people who are experienced at it.

Once the prep is complete a 5-piece mold will be pulled from the plug, then the first body will be made. I better move along with the chassis then! 03/31/09 Got some pictures of the molds being made. For the nose and tail below, the first picture is the plug with flange and mold release, then gel-coat, then glass.

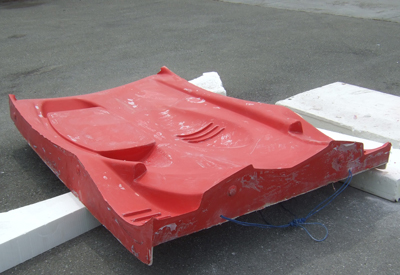

The mold splits are done so that we can make smaller sections for repairs of damaged shells, without having to replace the entire shell. A number of people have asked why I don't do the body in several sections that bolt, bond or latch together. The answer is that there are many pros and cons to each approach. With a multi-piece body there are issues with fit, fastening, paint matching, extra weight, rattles, etc. Also, the combination of several pieces will inevitably be more expensive than a single-piece whole because each piece will require its own layup, cure and finish labor and as much as 20% more material overall when you consider trim-away. The downside of a single-piece body is repairability. For larger cars multi-piece approach is pretty much unavoidable but I think for cars as small as mine, where the entire body is about the size of a nose section for a 'regular' car, the advantages of single-piece construction far outweigh the disadvantages. Consider that if you track something like a GT3, M3 or even an Elise, crunching a corner on the tire wall will cost you anything from $7-15K and I've seen over $50K damage to some Porsches at trackdays (and these days insurance doesn't cover track damage in most cases). Replacing an entire dp4 body will usually be cheaper than even a minor repair on a current production or a production-based sportscar (I'm not talking about Spec Miatas or IT Rabbits of course). And dp4 will be much faster than any of them :) 04/13/09 Work continues full speed at Contactscale and as these pictures show, the mold is now complete and ready for the first body to be made. The plan is for Dan to transport it up to Portland later in the week. This will be a wet-layup test body to check the mold and use it for the construction of the first prototype. Subsequent production units will be resin-infused with lightweight core for stiffness and to reduce weight.

This is definitely moving much faster than the prototype dp1 did :) I'm really looking forward to seeing the bodywork in the flesh. It'll be a big milestone. 04/17/09 Among all the other deliveries today (see other pages), Dan from Contactscale drove up from the Bay Area to visit and brought a test body for the dp4. What makes it a test body is the very thin, one-layer shell and minimal prep and finish.

This device does look pretty cool even if I say so myself. I want one. Despite being almost two feet shorter than the original dp1 the new design appears to be sleeker, at least to my eye. Which is exactly what I was hoping to achieve. The proportions are really fun. This particular bodyshell is not usable on a car but it will serve as a good fixture for confirming everything from driver's position to component clearances and such. this is rather fun actually.

|